Pool Pump Motor Amp Draw

Welcome to the Club!

Entry into thePool Owners Club does not come cheap. Besides the cost for installation, chemicals, repairs and fun accessories, there's also the utilities – water, gas and electric.

What's it cost to run a pool pump? How much of your hard earned cash goes to paying for the pump to run? These are the questions we hope to answer in today's post,

Specifically, how can you calculate the energy cost of running your pool pump? Is there an average energy use for pool pumps? And finally, what steps can be taken to reduce pump energy use?

How Much Does it Cost to Run a Pool Pump?

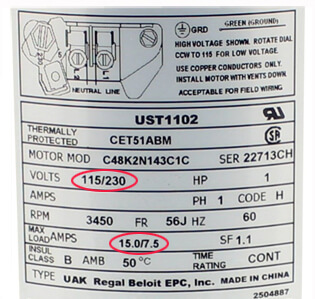

This can be figured out fairly easily, or approximated at least by checking the pump motor label and doing some calculations. On the pump label shown here (yours may look slightly different), you will find Volts and Amps listed. In this case, it shows volts as 115/230V which means that the motor is 'reversible' and can be operated at either 115V or 230V. The Amps are listed as 15.0 / 7.5 – which means that at 115V the motor draws 15A, and at 230V the draw is 7.5 Amps. For a larger motor over 2hp, you will commonly see only 230V listed and a single number to represent Amps used at maximum load.

This can be figured out fairly easily, or approximated at least by checking the pump motor label and doing some calculations. On the pump label shown here (yours may look slightly different), you will find Volts and Amps listed. In this case, it shows volts as 115/230V which means that the motor is 'reversible' and can be operated at either 115V or 230V. The Amps are listed as 15.0 / 7.5 – which means that at 115V the motor draws 15A, and at 230V the draw is 7.5 Amps. For a larger motor over 2hp, you will commonly see only 230V listed and a single number to represent Amps used at maximum load.

Note that the pump label or 'name plate' shows the Maximum Amp Draw. Many pool pumps after start-up, will pull 1-2 less amps than listed on the nameplate. They can also draw more amps than listed too, if it is too large for the system and plumbing, or there is a low-voltage problem. To get an exact reading of your amp draw, you could use an amp meter, but this requires technical several steps – Danny at Inyopools does a great job explaining how to use an ammeter on a pool pump.

The next steps involve some math:

- Multiply: Volts X Amps = Watts. In our particular example, assuming 230 volts, 230V x 7.5A = 1725 Watts

- Divide: Watts / 1000 = KiloWatts (Kw). In our example, 1725 / 1000 = 1.725 Kw

- Multiply:Kw X Hours per day of running the pump. For example, 1.725 Kw X 10 hours = 17.25 kWh per day

- Multiply:kWh/day X Cost per Kilowatt. For example 17.25 kWh X .12 cents/kWh* = $2.07 per day

*Your cost per kWh may be higher than the national average of 12 cents, some areas of expensive electricity pay double this amount, per kilowatt hour. Check your electrical bill / statement, or login to your 'paper-free' provider account online, to find out what your exact rate or fee is, per kilowatt hour (kWh).

How Much Energy do Pool Pumps Use?

It depends on how big your pump is, and how energy efficient it is. Larger horsepower pumps draw more amperage (which is what you really pay for), and thus more Kilowatt hours (kWh). Energy Efficient (EE) motors are less amp hungry than standard pump motors. Our 1 hp (standard) example UST1102 motor above will cost between $1-$5 per day, depending on what your power company charges per kWh, and on how many hours per day the pump is running, which changes within the season. This will result in a monthly cost of $30-$150.

A 2 hp pump won't pull twice as many amps as our 1 hp example motor UST1102, but it will be more, about 25% more, up to 20/10 amps. The EE version of our example motor, the UCT1102 'The Conservationist', uses 11 / 5.5 max load amps, or a reduction of just over 25%.

Our 1 hp example pump uses 1.75 Kw per hour; whereas a 2 hp motor of the same type (UST1202) would draw 2.4 Kw per hour. That's around 24 kWh per day, or around720 kWh per month, just running only 10 hors per day. During the heat of the summer, many pumps need to run longer to maintain clear water. And remember, pool pumps never get to take a day off.

Do 230V Pool Pumps Use Less Energy than 115V Pumps?

A 230V pump draws less amps than does a 115V (plug-in) pump – exactly half, but when you multiply it by twice the voltage, the Watts result is the same. For instance, returning to our example 1 hp motor and math calculations above, we deduced that 230V x 7.5A = 1725W, where Volts X Amps = Watts. Using 115V instead, the calculation looks like this: 115V x 15A = 1725W, or exactly the same.

A 230V pump draws less amps than does a 115V (plug-in) pump – exactly half, but when you multiply it by twice the voltage, the Watts result is the same. For instance, returning to our example 1 hp motor and math calculations above, we deduced that 230V x 7.5A = 1725W, where Volts X Amps = Watts. Using 115V instead, the calculation looks like this: 115V x 15A = 1725W, or exactly the same.

So, No – wiring up a pump with 230V instead of 115V will not reduce amperage draw (wattage consumed), or save money on your electrical bill. However, since each leg (wire) supplying power to pump is carrying only half (50%) of the amperage, there is less 'line loss' per line, or amperage that is lost. The savings in line loss is slight, but may be meaningful over the long term.

Does your pool pump use 115V or 230V?

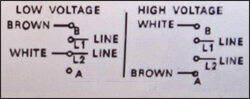

Most aboveground pool pumps use 115V, and most inground pumps use 230V; but it can be different. If your pump plugs into an 3 prong outlet, chances are it's 115V. Your motor label will tell you if your pump is 115V, 115V/230V or 230V. Now, if it says 115V/230V, it could be wired up either way, although it comes from the factory wired 230V, and most inground pools are wired with 230V. But if you want to be sure, you can look at the breaker box for the pump, usually a sub-panel or smaller 100amp breaker box, the usual gray color, near the pump. A double pole breaker is 230V, with two hot wires connected to it. Double pole breakers are about 1.5″ tall. Single pole breakers (115V) only have a connection for one wire, and are much thinner, about 3/4in tall. Another way; for those with a timeclock, the voltage may be listed inside on the label. Finally, a voltmeter can be used to test the power wires coming into the timeclock. Another way is to match the voltage diagram on your motor label, to how the wiring is connected on the terminal board, in the back where the wires connect. A pump labeled 115V/230V will come factory wired for 230V (high voltage) but can be switched to 115V (low voltage).Or your pump may be labeled just 115V or 230V, in which case it cannot be the other.

Ways to Reduce the Cost to Run a Pool Pump?

Here's a bunch of ways to reduce the amount of amps that are being consumed on the pool equipment pad. Some are more useful than others, or feasible for your case.

-

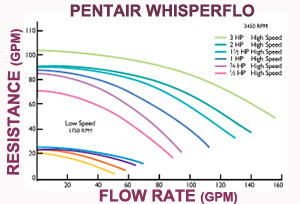

REDUCE PLUMBING & EQUIPMENT RESTRICTIONS: The pool pump has to overcome vacuum and pressure restrictions, and attempts to balance or straddle these two forces, at a point between the pump curve and system curve. Or said more plainly, the resistance that the pump must overcome is in proportion to the amount of Work the motor has to do. 2 inch plumbing is used on larger pumps, because the larger diameter has less resistance than 1.5 inch pipe. Larger pool filters are also less restrictive than smaller filters and run with lower filter pressure. Check valves, directional valves, chlorinators or purifiers all add restriction, as does a pool heater. Finally, the fewer bends in the pipes, to and from the pool, the better. Every bend or turn in the pipe adds resistance to the system. Total Resistance, as seen in a pump curve shown to the right, is a measure of all of the pipe, fittings, and other equipment (filter, heater, chlorinator, valves) resistance. Most pools are in the 20-40 ft of head, but some systems can run higher. Put even more plainly, if the plumbing pipe size can be increased, or redesigned for fewer bends and twists, and if unnecessary equipment is removed, or if the filter size is increased – these will reduce the Work for your pump motor, which will then need fewer amps, to get the work done.

REDUCE PLUMBING & EQUIPMENT RESTRICTIONS: The pool pump has to overcome vacuum and pressure restrictions, and attempts to balance or straddle these two forces, at a point between the pump curve and system curve. Or said more plainly, the resistance that the pump must overcome is in proportion to the amount of Work the motor has to do. 2 inch plumbing is used on larger pumps, because the larger diameter has less resistance than 1.5 inch pipe. Larger pool filters are also less restrictive than smaller filters and run with lower filter pressure. Check valves, directional valves, chlorinators or purifiers all add restriction, as does a pool heater. Finally, the fewer bends in the pipes, to and from the pool, the better. Every bend or turn in the pipe adds resistance to the system. Total Resistance, as seen in a pump curve shown to the right, is a measure of all of the pipe, fittings, and other equipment (filter, heater, chlorinator, valves) resistance. Most pools are in the 20-40 ft of head, but some systems can run higher. Put even more plainly, if the plumbing pipe size can be increased, or redesigned for fewer bends and twists, and if unnecessary equipment is removed, or if the filter size is increased – these will reduce the Work for your pump motor, which will then need fewer amps, to get the work done. -

RUN THE PUMP LESS: You have to be careful here, because if you are too skimpy with the energy usage, you'll end up paying much more in chemicals and filtering to bring the water back to good condition. But, you can experiment with how much time is needed for your pool to stay clean and clear, at any given time during the season. You will need more filtering when it's hot, perhaps double the amount during the hottest summer months, than you need during the cooler shoulder months. The actual amount needed for any pool depends on the efficiency and effectiveness of the pump and filter system. Pools with undersized systems will need to run the pump longer than pools with (larger) systems that have more effective filters and higher flow rates. Most pools are originally designed to turn-over all of the water in a pool within an 8-hour time period. For this reason, most pools should operate the pump at least 8 hours per day, up to 16 hours during periods of high use or high temperatures. Some sunbelt pools with good systems can get away with 4 hours daily during the off-season, but only when water temperatures are below 60 degrees. If you spend the time to experiment with your timeclock over the course of a week, you can find the tipping point where the pool starts to look a little hazy, not quite as bright and clear (all else being equal). Then set your timeclock for a few hours more than that cycle (you do have a timeclock, don't you?). For most pools it's a good idea to over-filter the water just a bit, so I usually recommend 12-15 hours daily, during pool season, but some pools can get away with less.

RUN THE PUMP LESS: You have to be careful here, because if you are too skimpy with the energy usage, you'll end up paying much more in chemicals and filtering to bring the water back to good condition. But, you can experiment with how much time is needed for your pool to stay clean and clear, at any given time during the season. You will need more filtering when it's hot, perhaps double the amount during the hottest summer months, than you need during the cooler shoulder months. The actual amount needed for any pool depends on the efficiency and effectiveness of the pump and filter system. Pools with undersized systems will need to run the pump longer than pools with (larger) systems that have more effective filters and higher flow rates. Most pools are originally designed to turn-over all of the water in a pool within an 8-hour time period. For this reason, most pools should operate the pump at least 8 hours per day, up to 16 hours during periods of high use or high temperatures. Some sunbelt pools with good systems can get away with 4 hours daily during the off-season, but only when water temperatures are below 60 degrees. If you spend the time to experiment with your timeclock over the course of a week, you can find the tipping point where the pool starts to look a little hazy, not quite as bright and clear (all else being equal). Then set your timeclock for a few hours more than that cycle (you do have a timeclock, don't you?). For most pools it's a good idea to over-filter the water just a bit, so I usually recommend 12-15 hours daily, during pool season, but some pools can get away with less. - INSTALL A VARIABLE SPEED PUMP:Variable speed pumps use lower speeds to consume less energy. When you reduce impeller speed (RPM) by half, you reduce the amperage required by 8 times! Basic models like the Superpump VS or Max-Flo VS have several speed options, which are pre-set. Full-featured VS pumps like the IntelliFlo or EcoStar are able to sense the required pressures and achieve a balanced harmony with the perfect impeller speed to get the job done. Variable Speed pool pumps can reduce energy consumption by 50-80%, so payback on their higher purchase price comes within a few years. VS pumps have another attractive quality in that their motors are quiet and cool permanent magnet motors, which last longer than traditional induction motors.

- INSTALL A TWO SPEED PUMP: Two Speed pumps (also called Dual Speed) are an improvement over single speed pumps, and can reduce energy use by 30% or more. Problem is, you also need a two speed timeclock, and add an extra wire from the clock to the pump, as the fourth, low-speed wire. This increases the cost to such a point that you may as well just buy a VS pump, which will have at least 3 speeds, contains its own timeclock, and uses the permanent magnet motor.

- INSTALL AN ENERGY EFFICIENT MOTOR: Most pumps that you buy online, or installed by a builder are using 'Standard' motors. But if you were to swap out a dying motor with the Energy Efficient (EE) or High Efficiency (HE) equivalent motor, you could reduce amp draw by 25%. This is done by using improved design concepts and materials that result in lower electrical loss.

- INSTALL A SMALLER HORSEPOWER PUMP: A lot of people don't know this, but not all 1 hp pool pumps produce the same amount of flow and pressure. There are medium flow, high flow and very high flow pumps. A 3/4 hp Whisperflo pump produces about the same flow rate as a 1.5 hp Superpump. Or a 1 hp Challenger pump can produce the same flow as a 2 hp Super Flo pump. A smaller pump horsepower translates to lower energy costs, because they use fewer amps. Replacing a medium-flow high-hp pump with a high-flow low-hp pump is what I'm talking about.

- INSTALL A BIGGER FILTER: And/Or a more effective filter. A pool filter that is more effective (like a DE filter) is so efficient at trapping dirt that less filter pump run time is possible. And a bigger filter is also going to have greater dirt trapping ability, but perhaps more importantly will have less resistance than a smaller filter. Running at lower pressure, the larger filter is less Work for the pump to push water through.

- INSTALL A SLIDE VALVE: If you have a choice in the matter, for sand and DE filters with sidemount valves, the Slide valve, aka Push-Pull valve has less resistance than a multiport style valve, especially in the 2 inch size. Cartridge filters, on the other hand, have no filter valve at all, and also can be a way to reduce filter resistance and motor work.

- KEEP YOUR WATER BALANCED: Giving the pool chemistry constant attention will prevent water problems from growing into something that requires running the pump longer to restore the water quality. Good water balance and sanitation practices reduces the need for additional filtration.

- USE SUPPLEMENTAL SANITIZERS: When your water is really sanitary, there is less work for the filter to do – fewer particles to remove from the water. Adding a secondary, or supplemental sanitizer (as I like to call them) like Nature2 or Ozone, or even using Clarifiers or Enzymes, can reduce your filtration demand, allowing you to run the pump less, while still keeping the water clean and clear.

Pool Pump Motor Amp Draw

Source: https://blog.intheswim.com/costs-of-running-a-pool-pump/

Posted by: buchananlatepred.blogspot.com

0 Response to "Pool Pump Motor Amp Draw"

Post a Comment